Geo Dynamics is again at the forefront in introducing yet another technology in India that is now popular worldwide. In 2006, we demonstrated that it is possible to generate a 3- dimensional image of the pile with sonic logging and using Tomography to the Indian deep foundation industry. We also demonstrated that the method can be applicable to any foundation type as long as pipes are left inside the pile before concreting. Today, Geo Dynamics has conducted tests for pile diameter ranging from 600mm to 3500mm diameter. We have successfully demonstrated how to repair pile shafts based on TOMOGRAPHY and findings obtained from core test results. We have created significant capabilities in the past decade to analyze and provide solutions to complex findings from the CSL test method. Geo Dynamics owns and operates several equipments spread throughout the country and abroad.

Method

The method is particularly useful for large diameter pile foundations for major structures like river bridges, towers, initial piles (before load testing). It can also be used for slurry walls or wall panels.

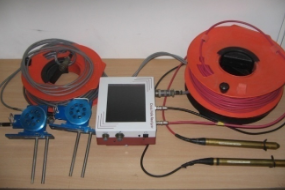

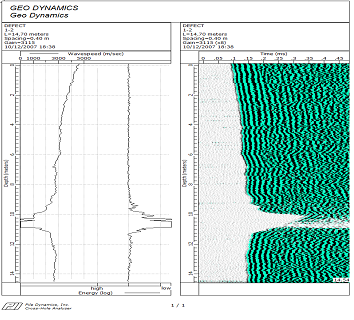

The Cross Hole Analyzer determines the quality and consistency of concrete between pairs of steel tubes pre-installed in bored piles, wall panels, concrete foundations. The output is in the form of waterfall map along with wave speed and energy or amplitude plot. Tomography software gives a good 2-D or 3-D image to visualize defects inside the pile for future corrective action. Typically one tube is installed for every 300mm diameter of pile and for diaphragm wall panels, the configuration is decided in advance based on the size of each wall panel. PVC tubes should be avoided as they lead to de-bonding issues which is basically loss of bond between pipes and concrete.

Single Hole Sonic Logging

Although not recommended by Geo Dynamics, we often test piles with only one pipe installed inside the pile which is also known as Single Hole Sonic Logging (SHSL). Single Hole Sonic Logging is mostly used for smaller diameter piles where using CSL testing is difficult as multiple tubes cannot be installed inside such piles. Typically SSL is used for pile diameters upto 600mm by installing a 38mm-50mm steel pipe inside the steel cage before concrete is cast. Although limited information is available due to only one tube, the method may determine major defects inside the pile and if defect is closer to the tube. Currently, many specifications prefer SSL testing as a part of their contract documents.

Benefits

The method is obviously superior to the low strain integrity testing as it gives an image between two pairs of tubes. Tomography helps identify location and extent of defect if atleast 4 tubes and six scans are available for a pile. This in some cases may help repair the pile shaft. Geo Dynamics has done significant work on repair and restoration of large diameter pile foundations which showed defect during initial testing. We have done extensive testing at the longest sea bridge in India, deep piles more than 70m depths large diameter piles upto 3.5m diameter etc. Some of projects can be listed as Mumbai Trans Harbour Link, Coastal Road Project, Mumbai, High Speed Rail Project in Gujarat, Bandra Worli Sea Link Project, and metro projects all over the country. Our current recommendation is to conduct 25% tests with this method for land piles and 100% tests for large diameter piles of 1.5m and above for both offshore and onshore projects.

Precautions

It should be ensured that owners and consultants get all the data including water fall diagram during report submission. Use of sub-standard quality tubes, improper installation may lead to blockage of tubes and the result will then be obtained only upto the depth of tubes scanned. Training is required before proper data collection and interpretation of the reports which otherwise may lead to avoidable controversies. All methods including CSL require understanding of piling operations, associated problems, knowledge of concrete and wave mechanics. Failure or inadequate knowledge may lead to serious errors resulting in loss of time and cost to the end user.

Code Compliance

Geo Dynamics complies with all requirements of ASTM D6760-2016 and various international codes that specify these tests. There is no Indian code currently for this test and a sub-committee is now formed to include Cross Hole Sonic Logging as a part of BIS.