High Strain Dynamic Pile Testing or PDA testing is a method to determine STATIC PILE CAPACITY using a dynamic impact. The method involves measurement of force and velocity response of the pile on field under the impact of a specified drop weight falling from a known height. The test is used in lieu of conventional static load testing. The test is conducted using Pile Driving Analyzer (PDA) and with its allied strain sensors and accelerometers. The entire equipment conforms to ASTM and other relevant standards worldwide.

The method is based on the Smith algorithm developed in 1960. In 1964 research was initiated in Case Western Reserve University under funding from Federal Highway Administration. By 1974, Dr. Goble and his associates had successfully demonstrated the use of this method and today it is a standardized test tool used worldwide and a part of various code specifications of various European, Asian and Americas.

The method is not related with any of the empirical formulae viz. Hiley’s Formulae, ENR, etc. It is based on the wave propagation theory and WAVE EQUATION approach studied by Smith in 1960. Today, such procedures based on Wave Propagation Theory are collectively called the Case Method and are conveniently applied in the field by dedicated electronic equipment called the Pile Driving Analyzer (PDA) system.

Use of empirical formulae such as Hiley’s or ENR or any modified formulae has been discarded worldwide due to various limitations and many assumptions involved. Such formulae were in use in 1950s before advent of computers and when not much information or Wave Equation type procedures were available. Using Hiley’s or ENR formulae can lead to dangerous situations and should be strictly avoided.

The HSDPT method as it is known as in the field is used in more than 30 countries and a part of codal provisions of ASTM, AASHTO in USA, also part of U.K., German, Australian, Dutch, Canadian and also various Asian countries.

In India, Geo Dynamics is the pioneer agency and leaders in this field. Typically we perform more than more than 1000 tests each year and we have conducted atleast 200 co-relation studies with good agreement between High Strain Dynamic Pile Test and Conventional Static Test at various projects all over India to ascertain its applicability in Indian conditions

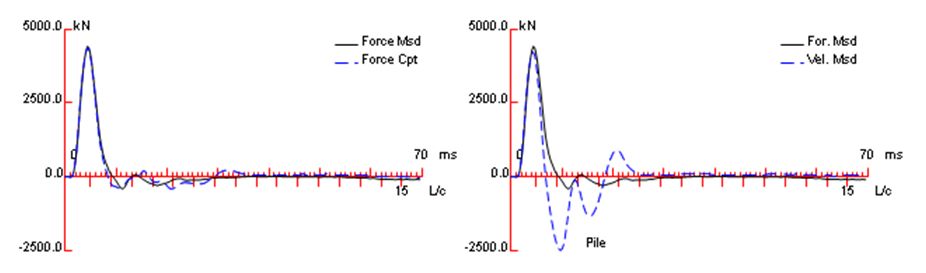

Case Pile Wave Analysis Program is an analytical method combining measured field data with pile wave equation type procedures, to refine the pile’s static bearing capacity estimated with PDA and to estimate the soil resistance distribution. Both measured and computed forces are plotted as a function of time and the iterative analysis is continued till there is good agreement between both the curves. It is essential that CAPWAP be done on piles subjected to PDA test especially for bored piles and few initial driven pile. Some other methods like SIMBAT do not own CAPWAP and hence lack the ability to correctly predict pile capacity and other parameters.

The output in case of PDA test is a measured force and velocity curve. A CAPWAP analysis that shows match between measured and computed force is also generated as displayed below. A simulated static test curve and variation of skin friction numerically and graphically also forms part of the report.

Pile Integrity Testing (PIT) also known as Low Strain Integrity Testing is performed to evaluate potential defects in the pile shaft qualitatively. Based on field information the type of defect can be identified. It is essential that the equipment used to conduct PIT conforms to ASTM D5882 and the test agency is trained to interpret the data.

Geo Dynamics is fully equipped with the latest PIT equipment available worldwide from the Pile Dynamics, Inc., original developers of this technology worldwide. We were the first to introduce the technology and prove its credibility all over India. Typically Geo Dynamics performs more than 10000 PITs every year.

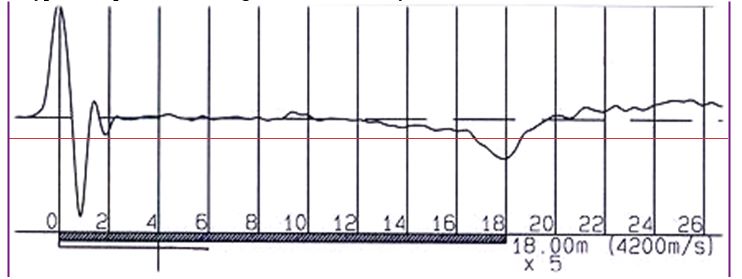

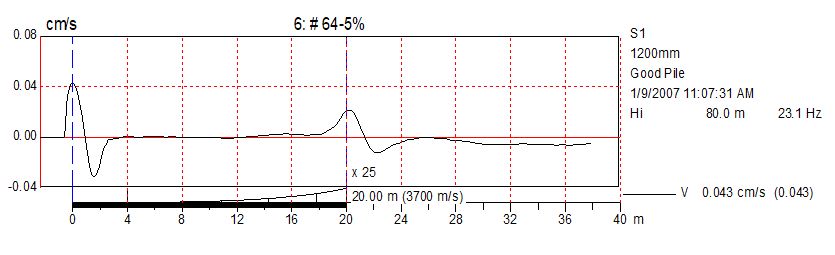

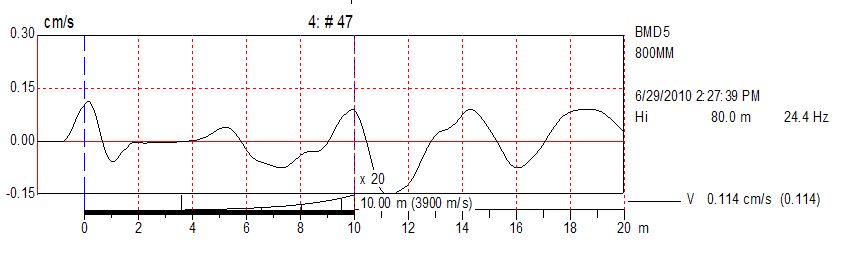

A typical output from PIT is given below for easy reference.

GOOD PILE

BAD PILE

The typical wave speed for concrete lies between 3300m/sec to 4200m/sec. For a reasonable length accuracy, the wave speed must be known. Assuming a reasonable value of 4000m/sec, it can be cross checked with the bore depth and concrete pour volume. Although the test system can be used to evaluate length of piles, the determination of pile length is approximate within a range of ± 5 – 10% due to variation in wave speed. This also implies that the method cannot evaluate defects that could be present in the bottom 5% -10% of the pile shaft for long friction piles.

The wave speed between 3700m/sec to 4100m/sec indicates consistent and good quality concrete however it is generally difficult to predict grade of concrete from wave speed due to its dependency on concrete density, percent reinforcement, presence of permanent liners, age of concrete etc.

The method does not evaluate minor defects and also multiple defects inside the pile as the wave generally reflects from the first major defect. Similarly, it may be difficult to evaluate the pile integrity beyond a major bulge and in such cases, it is likely that the pile integrity is inconclusive beyond major bulge or defect.

If the test results show a possible defect and toe is not evident, the location of the same is evaluated on the basis of an assumed wave speed of 4000m/sec. Thus some approximation in the location of defect is likely.

The method does not provide information on the pile capacity. The pile capacity can be obtained by static load test / high strain dynamic load tests or other equivalent methods.

The test method can generally evaluate for piles upto an L/D ratio of 45 to 50. However, this also depends on the soil resistance that may attenuate the signals and thus is a general statement. We have successfully performed PITs on piles more than 70m

Essentially HSDPT applies an impact load to calculate the axial load carrying capacity which is further refined by CAPWAP analysis to estimate skin friction and end bearing. The pullout capacity can be estimated as 80% of skin friction taking into account a factor of safety being applied to the total shaft resistance and the self-weight of the pile.

There is no thumb rule for maximum acceptable distance between the transmitter and receiver probes, however typically tube at every 300mm is installed for covering maximum pile area during the scans.

Following ASTM D6760 recommendation for every 250 to 300mm of pile diameter use one tube but a minimum of 3 tubes must be used.

Tubes of different diameters do not affect the overall results as long as they are large enough to allow movement of the probes since the software need the engineer to enter the internal diameters of the pipes and centralizers have been cautiously used while lowering the probes.

There are no recommendations for maximum diameter and Geo Dynamics has tested piles having diameter as high as 3.2m.

As far as sensors are concerned, 2 pairs are sufficient for the HSDPT test installed between 1.5 to 2 time diameters below the top of pile. However, this will result in evaluating bending in only one plane. For large diameter piles it is recommended to evaluate the bending in two planes for which 4 pairs of sensors can be attached.

Reinforcement extending cause vibrations interfering with signals from impedance changes below the top, this can however be taken care by Bending the reinforcements at site.